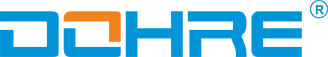

At present, the common processed materials include titanium alloy, high temperature alloy, high temperature stainless steel. DOHRE has already been working hard to serve customers in the aerospace manufacturing industry. Most of the engine blades used in the aerospace manufacturing industry are various standard carbide milling cutters, such as square end mill, ball nose end mill, corner radius end mill, forming cutter, also need face milling cutter and turning tool holders.

DOHRE established its branch in Chengdu in 2012, mainly for processing the blades of airplane steam turbines, tungsten steel inclined knives, and special cutter bars.

Operated a branch in Xi'an in 2020.

DOHRE has entered the China Hangfa Online Shopping Mall(http://www.aecc-mall.com) and has become one of 50 qualified suppliers in the milling cutter industry.

After nearly 10 years of providing ultra-high precision machining solutions, the company's product manufacturing system has achieved a qualitative leap under strict requirements and has become a leading domestic provider of high-end CNC cutting tools. Not only can we provide customers with high-quality tools, but also provide customers with feasible tool solutions.