3 Major Tips To Make End Mill For Stainless Steel Last Longer

Views: 1062

Author: Site Editor

Publish Time: 2021-12-28

Origin: Site

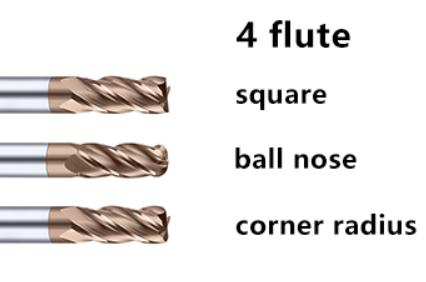

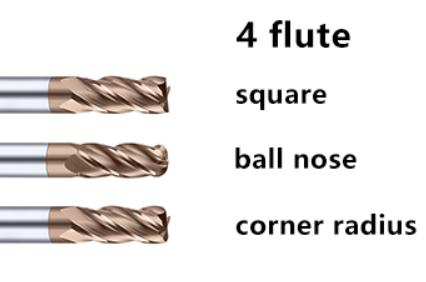

An end mill is a rotational cutting tool that is designed to remove material. It is designed with purpose and each shape provides a unique application. Any misuse of the tool can lead to a premature break.

To use your end mill longer without a premature break, it is essential to consider the following tips.

1. Coat End Mills

Coating of the cutting edges allows the end mill to endure high temperatures. The coating material acts to protect the edges from breaking as a result of high temperature.

There are different general-purpose coating materials you can choose for your end mill. Some of them are TiCN, TiN, and TiAIN. They slow down the tear and wear process of the tool when used under high temperature and fast speed rate.

It is essential to choose the right coating material for your tool. This is because different coating materials work better on different end mills. For instance, AITiN coating is not a perfect choice for aluminum. AITiN is aluminum-based, it is likely to form a build-up edge due to high attraction for each other.

2. Select The Right End Mill

To get it right, it is essential to choose the right tool at the commencement of work. Does the type of end mill suitable for the kind of work you want to do? This is an important question to ask before the selection of tools for the project.

When the right tool is used for the right work, the tool will last longer without damage. Also, check the exact geometries you require for a particular machining strategy and the type of material you are removing.

A quality end mill can remove material that ranges from hard metals to complicated plastics. When the correct kind of tool is selected, it will improve the performance and lifespan of the tool.

Furthermore, consider the kind of operation you want to carry out. Do you need high milling efficiency? How many flutes are ideal for the project? Do you want it for slotting, roughing, plunging, finishing, or contouring? The type of material and its application will also influence the length of the cut, cutter diameter, reach, and profile.

3. Protect The End Mill From Break

How do you protect your tool from premature break? You must avoid running the machine at the wrong speed. This is one of the most common mistakes that lead to the breaking of the end mill.

Sometimes, operators may want to run machines at higher speeds for more production. When the speed of the end mill is too fast, it leads to fractured cutting edges, improper chip sizes, or broken cutter.

It is advisable to determine the safe speed of the machinery before running the machine. Running a cutting tool outside the manufacturer's recommendation could result in damaged tools.

Contact Us For Quality End Mill For Stainless Steel

It is essential to maximize the use of your end mill without any break. The above tips will enable you to use your end mill for a longer period. As a reputable manufacturer, we produce quality end mills that are suitable for your project. Kindly click here to view.

In the mood of the festive season, we want to use this medium to wish you and yours a Merry Christmas and a Prosperous New Year 2022!!!

If any other question, please contact us:

- Tel: +86 769-85646282

- Email: info@dohrecnc.com

- Address: Room 203, Building 2, Songhu Zhigu Research Center, No. 6, Minfu Road, Liaobu Town, Dongguan, Guangdong, China