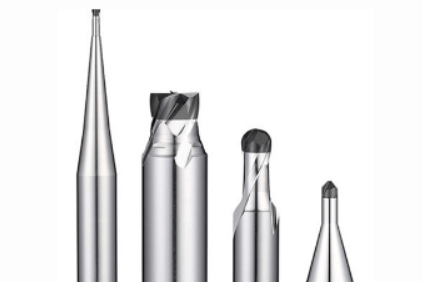

Different Types of End Mills

Views: 3647

Author: Site Editor

Publish Time: 2021-09-26

Origin: Site

Highly automated milling is a versatile machining process that is capable of producing components in almost any shape. There are a wide variety of CNC milling operations adopted for different manufacturing purposes. End milling mainly differs from other processes due to the type of tooling it is used for cutting materials. In this article, we’ll outline the types of end mills, what is end milling, and also figure out the difference between end mill and drill bit.

What is End Milling?

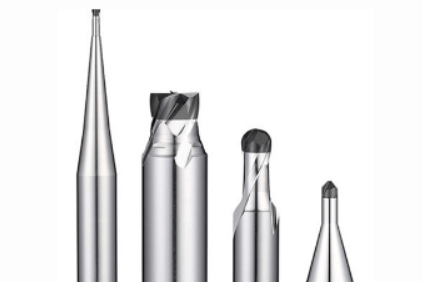

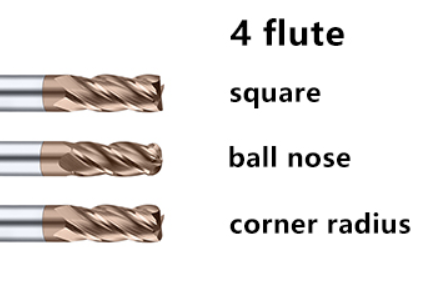

End milling is a type of milling process that can be used to produce slots, shoulders, die cavities, contours, profiles, and other milling parts. End milling uses the end mill which is a cylindrical cutter with multiple cutting edges on both its periphery and its tip, permitting end cutting and peripheral cutting.

What is End Mill?

The end mill is a type of milling cutter designed to be able to cut axially and applicable in end milling, profile milling, tracer milling, face milling, and plunging. End mills and other cutting tools can be made from a host of materials, such as the carbide inserts (suitable for high production milling), high-speed steel (when a special tool shape needed), ceramics inserts (for high-speed machining with high volume), and diamond inserts (offer tight tolerances). High-speed steel (HSS) and tungsten carbide are two of the most common materials for making the end mill. End mills allow precision cutting to manufacture milled parts for broad applications, including jewelry, sign making, mold making, circuit boards, wood engravings, machine parts, and more. Endmills are available in varying lengths, diameters, flutes, and types.

Common Type of End Mills

Straight Flute End Mills

As their name suggests, straight flute end mills have ‘straight’ and basic flutes, are single-ended and have a zero degree helix. The straight flute reduces the fraying of a workpiece’s edges and provides a good surface finish. They are used to mill plastics, composites of epoxy and glass, and for special profile milling applications.

Up and Down Cut End Mills

Up-cut and down-cut end mills are spiral shaped. The spiral either carries the residue chips up and away from the designated area (in an up-cut), giving it a fairly rough finish or carries them down (in a down-cut) for a smoother top finish. An up-cut end mill keeps the bit cool as it quickly removes materials, which is essential for cutting softer materials like plastic or aluminum. However, it can cause wear to the top surface and may lift materials up so that hold-downs are required to keep the workpiece in place. Down-cut end mills create a smooth top surface on laminates, and hold down thin parts, and are better at avoiding tabs on larger parts.

Ball-Nose End Mills

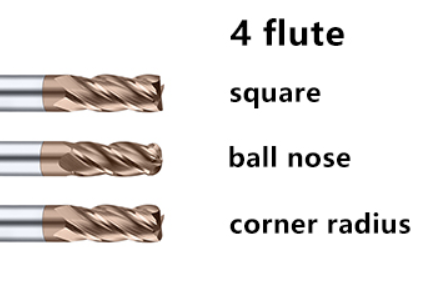

Ball-nose end mills, also known as a "ball end mills,” have rounded tips. They can be single-ended or double-ended. They can be general purpose or can have high-performance geometries. They are used for milling a large corner radius, grooving with a full radius, and contour or profile milling. The smaller diameters are used for engraving, and often for 3D tooling.

Roughing End Mills

Roughing end mills have scallops on the outside diameter that cause the metal chips on a workpiece to break into smaller segments. This results in lower cutting pressures at a given radial depth of cut. Roughing end mills are mainly used, as their name suggests, for rough milling material off when removing large amounts of material. There are many different helix angles and flute configurations possible with roughing end mills, because of the many different materials that can be milled.

V-Bit End Mills

V-bit end mills are used for carving V-shaped depressions in the workpiece, also called V-carving. They come in either 60° or 90° V-bit. The sharp tips of the end mills are used to cut through narrow paths, while the wider bottom is used for larger cuts. This tapered end mill is best for especially sharp edges and corners, because of their radiuses.

Summary

This article presented an understanding of the different types of end mills. For more information on related products, consult our other guides or contact us directly.

If any other question, please contact us:

- Tel: +86 769-85646282

- Email: info@dohrecnc.com

- Address: Room 203, Building 2, Songhu Zhigu Research Center, No. 6, Minfu Road, Liaobu Town, Dongguan, Guangdong, China