Tips For Choosing The Right End Mill

Views: 1060

Author: Site Editor

Publish Time: 2021-11-11

Origin: Site

Choosing the Right End Mill for Your Job

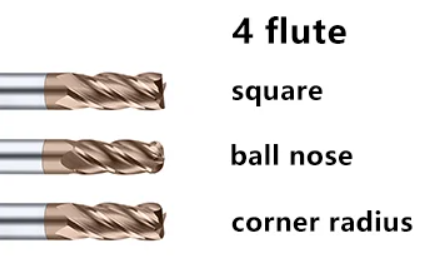

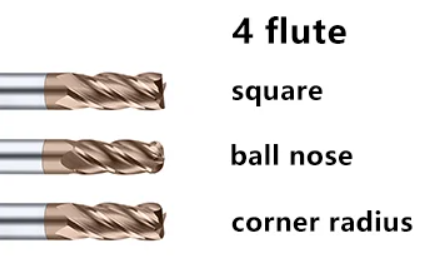

End mills are designed with purpose and each tip shape offers a unique clearing path for various applications. Deciphering what end mill to choose is largely based on the project, what kind of material needs to be cut and the desired surface finish. Choosing the wrong cutting tool can quickly damage a work piece, causing you to scrap an entire batch. Not only is that a huge waste of time, but also a significant cost to your organization.

There’s a lot to consider when choosing the right end mill for your CNC operation. We’ve pared down a few important tips to help you select the right end mill.

Three major factors will influence your choice :

ü What kind of shapes do you want to mill (2D contour, 3D shape, holes,...)?

ü What kind of material do you want to mill?

ü What are your goals in terms of performance and surface finish, while keeping an acceptable cost for you and staying within the capabilities of your CNC machine?

Overall length

Imagine you want to mill a very deep pocket inside a high part. You will need a long tool to be able to machine the bottom without colliding your spindle mandrel with the stock of the material. Hence, the length of your end mill will be determined by how deep it must penetrate into the material. The associated concept with this observation is called “stickout”. It is defined by the distance from the end of the tool holder to the tip of the end mill.

Also, keep in mind that the cutting depth should never exceed the flute length of your end mill. If cutting deeper than the length of the flutes, chips won’t clear properly, heat will build up and you risk to damage your tool.

At this point, it might seem smart to buy end mills that are as long as possible to have the flexibility to use them in more situations, right? It’s actually not the case, because the more stickout, the less rigid a tool is. If it sticks out too far and you work it too demanding, the cutting forces will make it bend, which is what is called “tool deflection.”

Number of flutes

Flutes are the deep spiral grooves that allow chip formation and evacuation. They are the part of the end mill anatomy that create those sharp cutting edges (sometimes referred to as “teeth”).

he number of flutes on your end mill is a crucial parameter that depends mostly on the material you want to cut and on the capabilities of your machine. Indeed, the number of flutes on your end mill will impact:

ü the feed rate of your machine,

ü the surface finish of your piece, and

ü the ability of the tool to clear chips.

End Mill Materials

Two of the most common materials used in the manufacturing of end mills are high speed steel (HSS) and carbide. HSS is useful in older, slower, or less rigid machines as well as one off or very short run production. It will run slower, but is less expensive, less brittle and more forgiving of unstable conditions. Carbide is preferred in CNC machine tools where higher speeds, fewer tooling changes and increased productivity are required. In these applications, the higher cost is easily justified by longer tool life and shorter cycle times.

In need of end mill supplier?

Whatever the job, we are proud to carry a wide range of end mills designed to give you an edge over the competition. If you have questions about selecting the right end mills or other cutting tools for your operation , we’re here to help.

If any other question, please contact us:

- Tel: +86 769-85646282

- Email: info@dohrecnc.com

- Address: Room 203, Building 2, Songhu Zhigu Research Center, No. 6, Minfu Road, Liaobu Town, Dongguan, Guangdong, China