Tips of Buying Carbide Inserts

Views: 1834

Author: Site Editor

Publish Time: 2021-07-12

Origin: Site

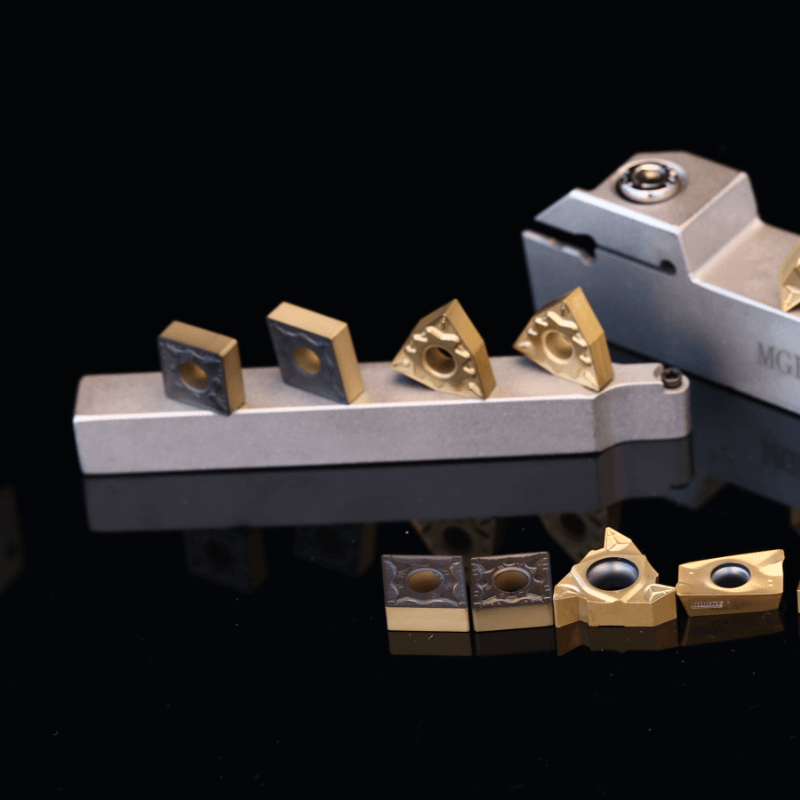

Carbide inserts are replaceable and usually indexable bits of cemented carbide used in machining steels, cast iron, high temperature alloys, and nonferrous materials. Carbide inserts allow faster machining and leave better finishes on metal parts. Carbide inserts can withstand higher temperatures than high speed steel tools.

How to choose carbide inserts?

There are many parameters to consider when choosing a carbide insert. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining performance.

· Select insert geometry based on selected operation, for example finishing

· Select the largest possible nose angle on the insert for strength and economy

· Select the insert size depending on the depth of cut

· Select the largest possible nose radius for insert strength

· Select a smaller nose radius if there is a tendency for vibration

What are carbide inserts made of?

It consists of fine particles of carbide cemented into a composite by a binder metal. Cemented carbides commonly use tungsten carbide (WC), titanium carbide (TiC), or tantalum carbide (TaC) as the aggregate. Mentions of "carbide" or "tungsten carbide" in industrial contexts usually refer to these cemented composites.

How do you identify carbide inserts?

Every carbide insert can be identified using the Turning Tool ISO code system. This straightforward shorthand system covers everything you need to know, and need to tell us, when ordering your new carbide insert.

The ISO code is based on the metric system, with measurements made in millimetres. In America, they use a different system called the American National Standard ANSI B212.4-2002 system that uses inches. We don't cover that in this guide.

Every carbide insert has an identification code attached to it. This isn't a random collection of letters and numbers, but a comprehensive system that can help you identify the correct tool.

Shop for Carbide Inserts by Shape

1. P Series Insert For Steel

DPF/DTF chip breaker is suitable for ISO P finishing machining

DPM/DPMK/TM chip breaker is suitable for ISO P medium finishing Roughing machining

DPR/DTR chip breaker is suitable for ISO P roughing machining

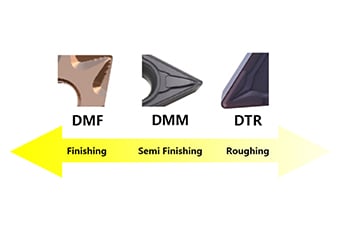

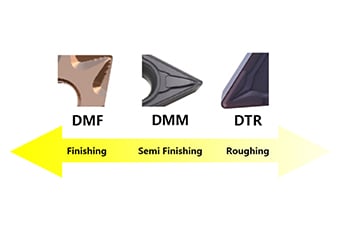

2. M Series Insert For Stainless Steel

DMF/DTF chip breaker is suitable for ISO M finishing machining

DMM/DMA chip breaker is suitable for ISO M medium finishing Roughing machining

DTR chip breaker is suitable for ISO P roughing machining

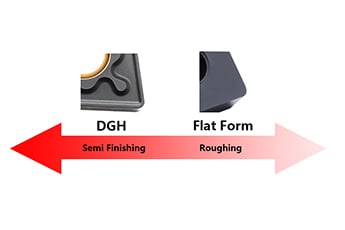

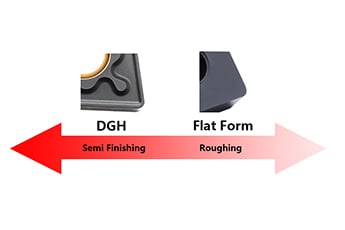

3. K Series For Cast Iron

DZT/GHB chip breaker is suitable for ISO K medium finishing

Flat form(no chip breaker) is suitable for ISO K roughing machining

4. N series for Aluminum Alloy

AK form designed for ISO N finishing machining

ALH form designed for semi finishing to roughing for N ISO

About Us

Dohre is a professional manufacturer and technology solution provider, with a passion for bringing you high quality,favourable prices ,fast delivery and full technology support. If you are interested the products we have, please don't hesitate to contact us!

If any other question, please contact us:

- Tel: +86 769-85646282

- Email: info@dohrecnc.com

- Address: Room 203, Building 2, Songhu Zhigu Research Center, No. 6, Minfu Road, Liaobu Town, Dongguan, Guangdong, China