Product Description

Feature

• High quality material, Lasting durable, Precision machining, Work efficiently

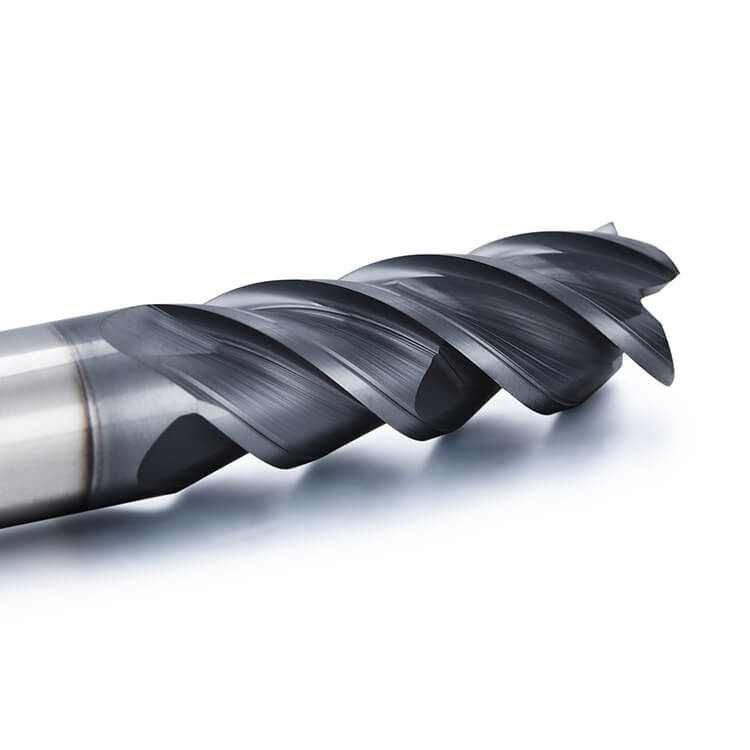

• The new fine grain tungsten steel base material has high wear resistance and strength, all round milling cutter for high hardness and high speed cutting applications.

• The cutting edge is covered with high quality coating, which can enhance the wear resistance of milling cutter and improve the wear resistance of cutter body lubricity to ensure tool life and improve work efficency.

• Double edge belt, 45° helix angle design, high rigidity and wear resistance, good for large cutting during machining, the burr of workpiece is reduced and the tool is not easy to stick.

• Using chip removal groove design, chip removal is smooth and effective in the process of processing Reduce the collapse and wear of products. Unique spiral blade angle, sharp and wear-resistant, The cutting is smooth and the cutting efficiency is greatly improved.

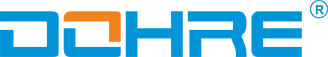

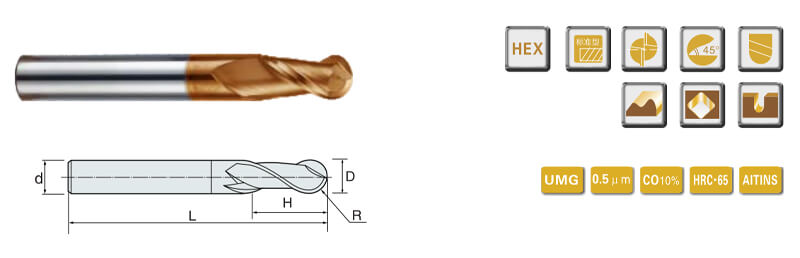

Specification

| Type | Specification | R | Flute Length(D) | Shank dia(d) | Overall L |

| Standard | R0.5X2XD3X50L | R0.5 | 2 | 3 | 50 |

| R1.0X4XD3X50L | R1 | 4 | 3 | 50 |

| R0.50X2XD4X50 | R0.5 | 2 | 4 | 50 |

| R0.50X2XD6X50 | R0.5 | 2 | 6 | 50 |

| R0.75X3XD4X50 | R0.75 | 3 | 4 | 50 |

| R0.75X3XD6X50 | R0.75 | 3 | 6 | 50 |

| R1.00X4XD4X50 | R1 | 4 | 4 | 50 |

| R1.00X4XD6X50 | R1 | 4 | 6 | 50 |

| R1.25X5XD4X50 | R1.25 | 5 | 4 | 50 |

| R1.25X5XD6X50 | R1.25 | 5 | 6 | 50 |

| R1.50X6X3X50 | R1.5 | 6 | 3 | 50 |

| R1.50X6XD4X50 | R1.5 | 6 | 4 | 50 |

| R1.50X6XD6X50 | R1.5 | 6 | 6 | 50 |

| R1.75X7XD4X50 | R1.75 | 7 | 4 | 50 |

| R1.75X7XD6X50 | R1.75 | 7 | 6 | 50 |

| R2.00X8XD4X50 | R2.0 | 8 | 4 | 50 |

| R2.00X8XD6X50 | R2.0 | 8 | 6 | 50 |

| R2.25X9XD6X50 | R2.25 | 9 | 6 | 50 |

| R2.50X10X5X50 | R2.5 | 10 | 5 | 50 |

| R2.50X10X6X50 | R2.5 | 10 | 6 | 50 |

| R2.50X10X6X60 | R2.5 | 10 | 6 | 60 |

| R2.75X11XD6X50 | R2.75 | 11 | 6 | 50 |

| R2.50X10XD6X50 | R2.5 | 10 | 6 | 50 |

| R3.00X12XD6X50 | R3.0 | 12 | 6 | 50 |

| R3.25X13XD8X60 | R3.25 | 13 | 8 | 60 |

| R3.50X14XD8X60 | R3.5 | 14 | 8 | 60 |

| R3.50X14XD7X60 | R3.5 | 14 | 7 | 60 |

| R3.75X15XD8X60 | R3.75 | 15 | 8 | 60 |

| R4.00X16XD8X60 | R4.0 | 16 | 8 | 60 |

| R4.50X18XD10X75 | R4.5 | 18 | 10 | 75 |

| R5.00X20XD10X75 | R5.0 | 20 | 10 | 75 |

| R6.00X24XD12X75 | R6.0 | 24 | 12 | 75 |

| R7.00X40XD14X100 | R7.0 | 40 | 14 | 100 |

| R8.00X40XD16X100 | R8.0 | 40 | 16 | 100 |

| R8.00X30XD16X100 | R8.0 | 30 | 16 | 100 |

| R9.00X40XD18X100 | R9.0 | 40 | 18 | 100 |

| R10.0X40XD20X100 | R10.0 | 40 | 20 | 100 |

| R12.5X40XD25X100 | R12.5.0 | 40 | 25 | 100 |

NOTE:

1. During using, appropriately reduce the cutting speed and feed rate, which can prolong the service life of the milling cutter.

2. When working, it is necessary to add cutting fluid to protect the knife edge, so that the cutting is smoother.

3. When the oxide film or other hardened layer remains on the surface of the workpiece, it can be removed by reverse milling.

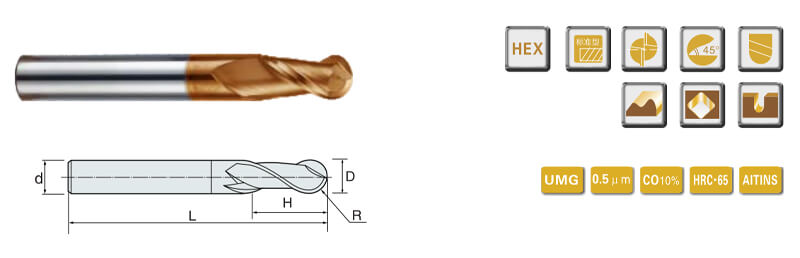

Detailed Images

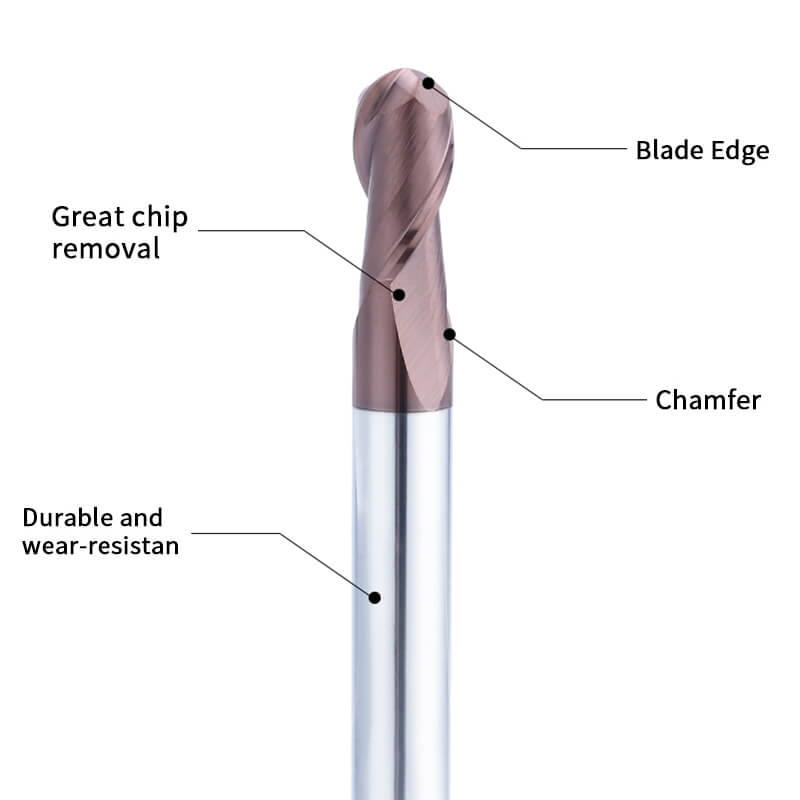

| Details •The arc relief angle makes the tool more wear-resistant, the flat relief angle makes the tool sharper and stronger, the cutting process is lighter and faster, and the tool life is longer under the double cooperation. •Smooth chamfering, easy and fast installation of the chuck, high gloss surface.

• Large chip removal design

|

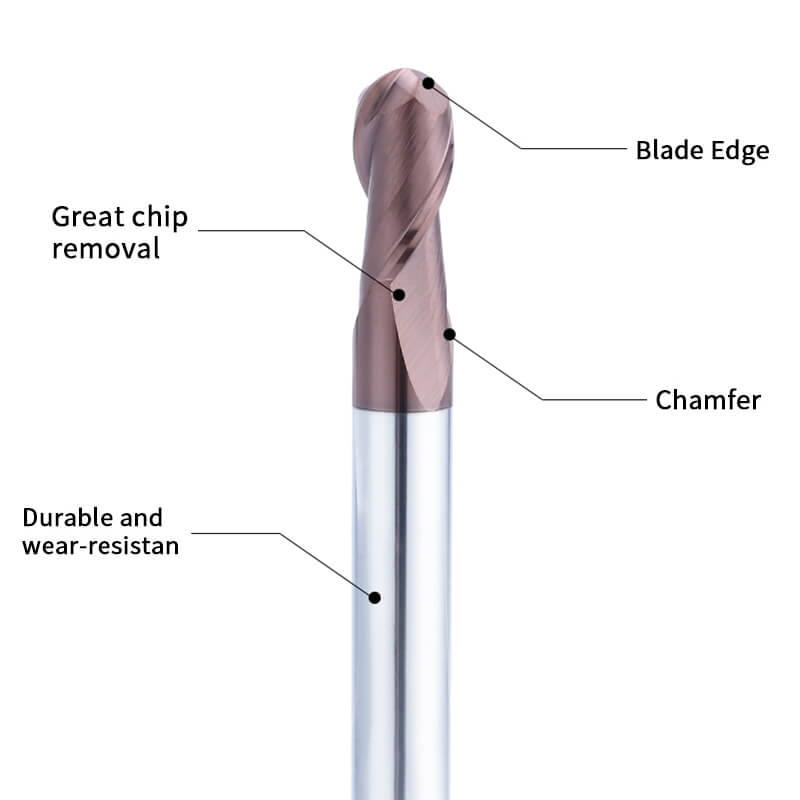

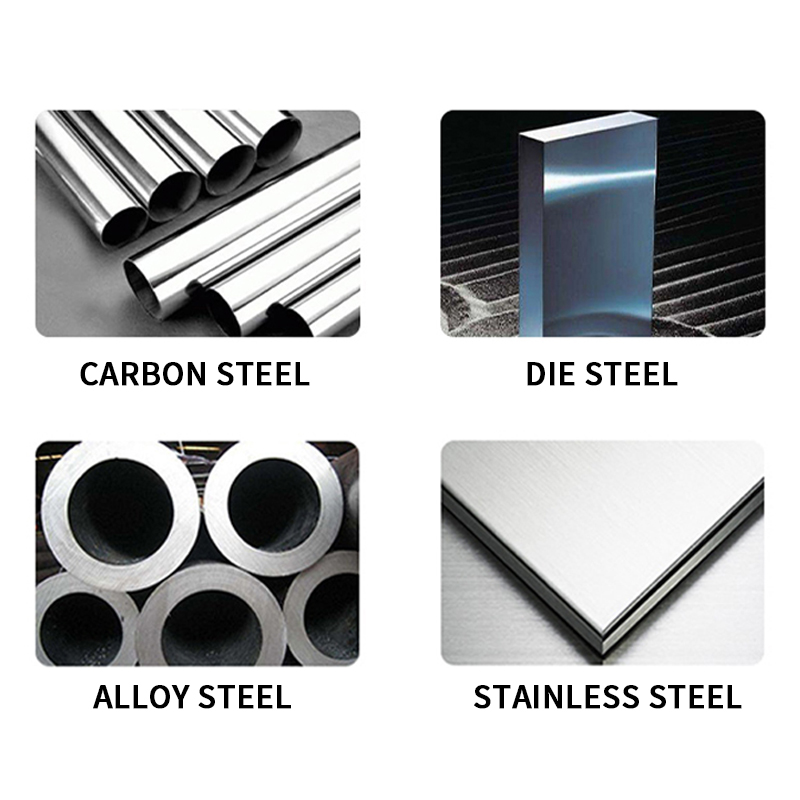

| AITIN-S application range: •Suitable for high-efficiency cutting processing of ordinary steel, pre-hardened die steel cast iron, copper, alloy steel, ductile cast, and processing of materials with hardness below HRC65 degrees.

•The AS COATING coating made with Japanese advanced technology and equipment contains heat-resistant element silicon, which not only has high temperature oxidation resistance (1100°C), but also can exert the best performance on processing tools under dry or high-speed conditions.

• Types: End mills, ball end mills, round nose milling cutters, can meet the finishing of your product surface quality. |

Advantages

ISO Certification

|

|

|

Packing&Shipping

FAQ & Contact Us