Product Description

| ○ General | ● Suitable | ▲ Very suitable |

| ISO Material group | P | M | K | N | S | H |

| workpiece material | Carbon Steel | Alloy Steel、 Tools Steel | Stainless Steel | Cast iron

| Aluminum Alloy | Cooper Alloy | Graphite | Heat ResistantAlloy | Titanium Alloy | Pre-hardened Steel

Hardened Steel |

| products series | hardness | ~20HRC | ~30HRC | ~35HRC | ~350HB |

|

|

|

|

| ~45HRC | ~55HRC | ~60HRC | ~65HRC |

| GEX | HRC45 | ● | ○ | ○ |

|

| ○ |

|

|

|

|

|

|

|

| PEX | HRC55 | ○ | ● |

| ● |

|

|

|

|

|

|

|

|

|

| UEX | HRC60

|

|

|

|

|

|

|

|

|

| ● | ○ | ○ |

|

| P-UEX |

|

|

|

|

|

|

|

|

| ● | ○ | ○ |

|

| HEX | HRC65

|

|

|

|

|

|

|

|

|

| ○ | ● | ● | ○ |

| P-HEX |

|

|

|

|

|

|

|

|

| ○ | ● | ● | ○ |

| CEX | HRC70

|

|

|

|

|

|

|

|

|

|

| ● | ○ | ○ |

| P-CEX |

|

|

|

|

|

|

|

|

|

| ● | ○ | ○ |

| AEX | HRC50 |

|

|

|

| ● | ● |

|

|

|

|

|

|

|

| FEX | HRC58 |

|

|

|

| ● | ● |

|

|

|

|

|

|

|

| P-FEX | HRC58 |

|

|

|

| ● | ● |

|

|

|

|

|

|

|

| MEX | HRC50 |

|

|

|

|

|

| ● |

|

|

|

|

|

|

| TEX | HRC55 |

|

| ▲ |

|

|

|

| ○ | ● |

|

|

|

|

SPECIFICATION

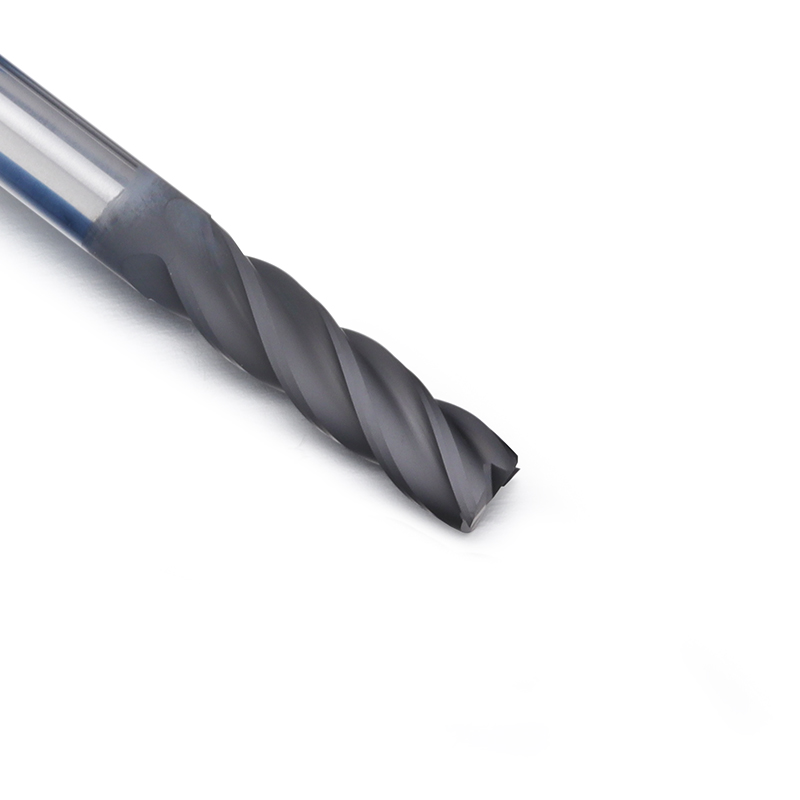

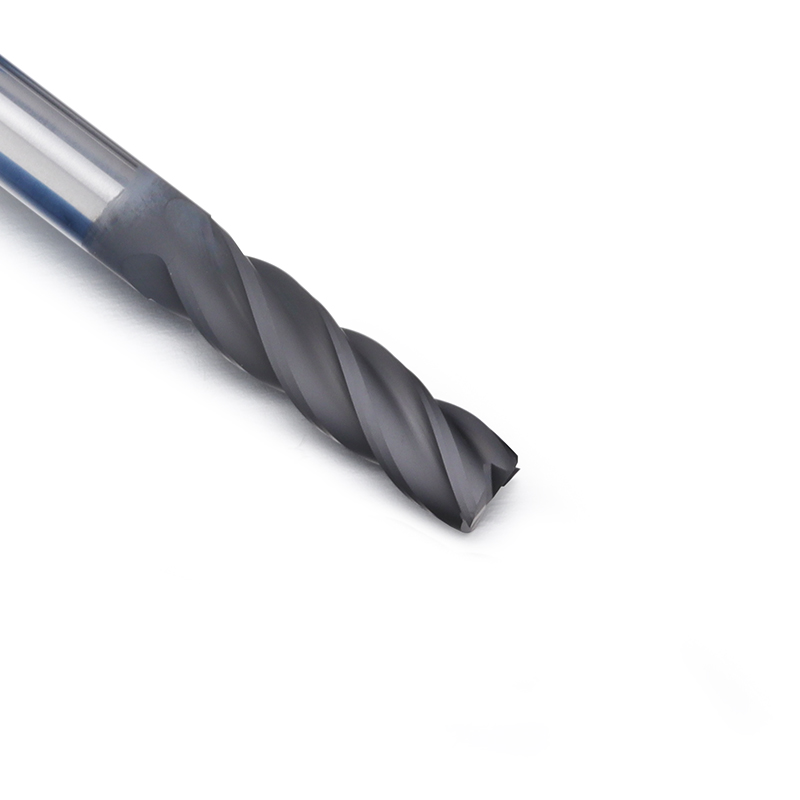

Features:

1.Range of application: use for ordinary stainless steel, ordinary mould steel, Hardened common steel, cast iron, copper, alloy steel with high effective process. Suitable for processing material with hardness below HRC65.

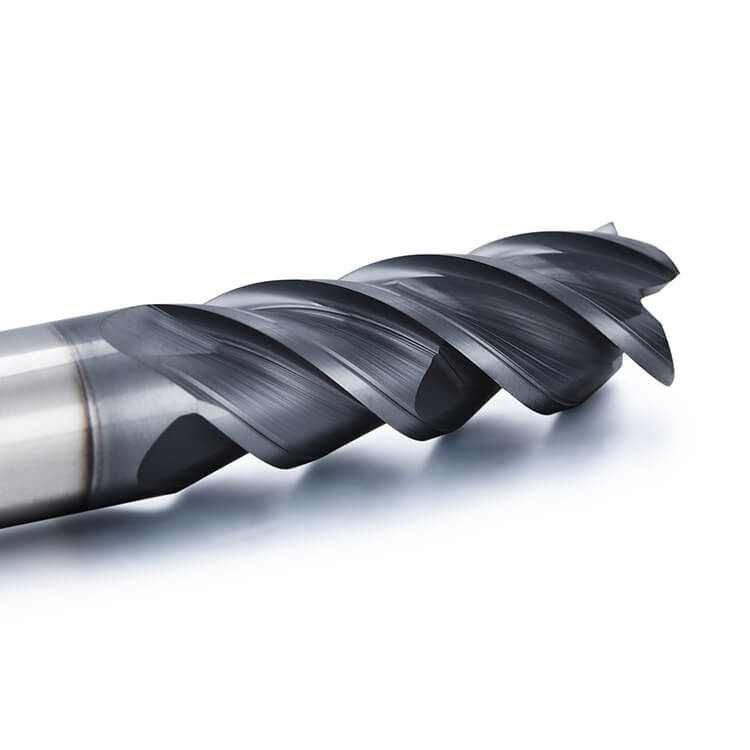

2. Structure of cutting tools : The sharp cutting matched with the good hardness ,Arc relief angle makes tool better wear-resistance, flat relief angle makes tool sharper. Cutters with two kinds of relief angle, cutting process will be faster, and tools will be longer life. Cross-center of flute top make drilling and milling better.

3. Coating of cutting tools: AlTIN coating, adopted advanced technology and equipement of Japan, Not only has high temperature oxidation resistance (800 °C), but also can achieve best on the condition of dry machining or high speed cutting.

4. The advanced technology and equipment imported from Germany.

5. Toppest materials of around the world (TaeguTec, Kennametal, AF K34/K44).

6. Multi-series of product supported: Square end mill, Ball nose end mills, Corner radius cutting tools, Roughing end mill, Long neck short flute end mill,etc.

Technology:

1. Blade Point

Blade belt: double blade belt design is adopted to determine a more wear-resistant edge.It adopts a blade design suitable for high-speed cutting,with a 2-blade edge and excellent chip removal!

2. Mirror chip removal slot

High capacity chip removal with strong cutting,smooth cutting discharge,can achieve high effiency machining.

3. Chamfering

Perfect chamfering,easy and fast installation chuck,high gloss knife body import essential features.

| MEX | Flutes

| Processing Forms

| Helix Angle

| Coating

| Hardness

|

| 2 Flute graphite ball nose end mills | 2 | Surface/Hole/Keyway | 30º | DIA | HRC50 |

| 4 Flute graphite square end mill | 4 | Side/Side and flat Surface/ Keyway | 30º | DIA | HRC50 |

| 4 Flute graphite corner radius end mills | 4 | Side/Side and flat Surface/ Keyway | 30º | DIA | HRC50 |

Advantages

1.Ultrafine crystal grains, mirror processing effect, long service life.

2.Surface finish less than 0.4u, mirror effect and very shinning.

3.Wear-resistant and very long work life, much more than carbide materials.

4.Four times of cutting tool detection to ensure the quality

| 1) The first piece, the tail piece and the sampling inspection in the production process with Helicheck PlusWalter equipment to full inspection the Circumferential Rake, circumferential edge back Angle, end tooth front Angle, end tooth back Angle, R Angle value and profile, the profile of the forming knife |

(2) after production , full inspection by two dimensions measuring instrument or Microscopic,flute number,outer diameter,flute length ,core diameter,helical angle,width of relief angle,End Tooth Eccentricity and end tooth throught a center,Disc angle of end tooth,Outside run-out and Whether there are notches, jagged

|

(3) before coating Spot check by two dimensions measuring instrument

|

(4)After coating full inspection by two dimensions measuring instrument

|

3.excellent R&D teams and professional technology support teams

FAQ & Contact Us

Q: Are you trading company or manufacturer ?

| A: Yes ,We are factory for more than 10 years in CNC tools. |

| Q: How long is your delivery time? | A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to |

| Q: Do you provide samples ? is it free or extra ? | A: No, we don't provide samples, we we can offer you some discounts depends on your order quantity. |

| Q: What is your terms of payment ? | A: T/T 30% deposit,70% balance against B/L copy or 100% irrevocable LC at sight. More payment terms available(Paypal, Western Union) |

Q: Do you make OEM ?

| A: Yes, we do. OEM is accepted with your brand lase in the products by our laser machine and label of the OEM brand would be stuck on the box before goods shipped out. |

| Q: What the machine do you adopt to produce the products ? | A: We use the walter which imported from Germany. |