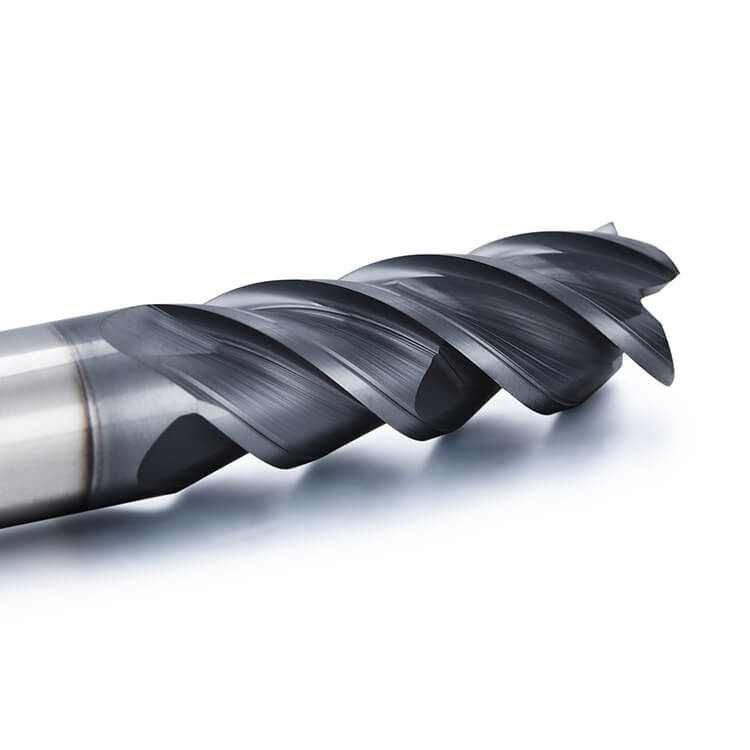

Features:

1.Range of application: use for ordinary stainless steel, ordinary mould steel, Hardened common steel, cast iron, copper, alloy steel with high effective process. Suitable for processing material with hardness below HRC65.

2. Structure of cutting tools : The sharp cutting matched with the good hardness ,Arc relief angle makes tool better wear-resistance, flat relief angle makes tool sharper. Cutters with two kinds of relief angle, cutting process will be faster, and tools will be longer life. Cross-center of flute top make drilling and milling better.

3. Coating of cutting tools: AlTIN coating, adopted advanced technology and equipement of Japan, Not only has high temperature oxidation resistance (800 °C), but also can achieve best on the condition of dry machining or high speed cutting.

4.The advanced technology and equipment imported from Germany.

5.Toppest materials of around the world (TaeguTec, Kennametal, AF K34/K44).

6.Multi-series of product supported: Square end mill, Ball nose end mills, Corner radius cutting tools, Roughing end mill, Long neck short flute end mill,etc.

Technology:

1.Blade Point

Blade belt: double blade belt design is adopted to determine a more wear-resistant edge.It adopts a blade design suitable for high-speed cutting,with a 2-blade edge and excellent chip removal!

2.Mirror chip removal slot

High capacity chip removal with strong cutting,smooth cutting discharge,can achieve high effiency machining.

3.Chamfering

Perfect chamfering,easy and fast installation chuck,high gloss knife body import essential features.

| FEX | Flutes

| Processing Forms

| Helix Angle

| Coating

| Hardness

|

| Single Flute End Mill(A.For Aluminum) | 1 |

| 40º | No/DLC | HRC50/HRC55 |

| Single Flute End Mill(A.For Acrylic) | 1 |

| 40º | No/DLC | HRC50/HRC55 |

| 2 Flute Aluminum square end mill | 2 | Side/Side and flat Surface/ Keyway | 45º | No/DLC | HRC50/HRC55 |

| 2 Flute long Aluminum square end mill | 2 | Side/Side and flat Surface/ Keyway | 45º | No/DLC | HRC50/HRC55 |

| 2 flute Aluminum Ball Nose End Mill | 2 | Surface/Hole/Keyway | 45º | No/DLC | HRC50/HRC55 |

| 3 Flute Aluminum Square End Mill | 3 | Side/Side and flat Surface/ Keyway | 45º | No/DLC | HRC50/HRC55 |

| 3 Flute long Aluminum Square End Mill | 3 | Side/Side and flat Surface/ Keyway | 45º | No/DLC | HRC50/HRC55 |

| 3 Flute Aluminum Square End Mill | 3 | Side/Side and flat Surface/ Keyway | 55º | No/DLC | HRC50/HRC55 |