Product Description

Production

parameter

| ○ General | ● Suitable | ▲ Very suitable |

| ISO Material group | P | M | K | N | S | H |

| workpiece material | Carbon Steel | Alloy Steel、 Tools Steel | Stainless Steel | Cast iron

| Aluminum Alloy | Cooper Alloy | Graphite | Heat ResistantAlloy | Titanium Alloy | Pre-hardened Steel

Hardened Steel |

| products series | hardness | ~20HRC | ~30HRC | ~35HRC | ~350HB |

|

|

|

|

| ~45HRC | ~55HRC | ~60HRC | ~65HRC |

| UEX | HRC60

|

|

|

|

|

|

|

|

|

| ● | ○ | ○ |

|

| P-UEX |

|

|

|

|

|

|

|

|

| ● | ○ | ○ |

|

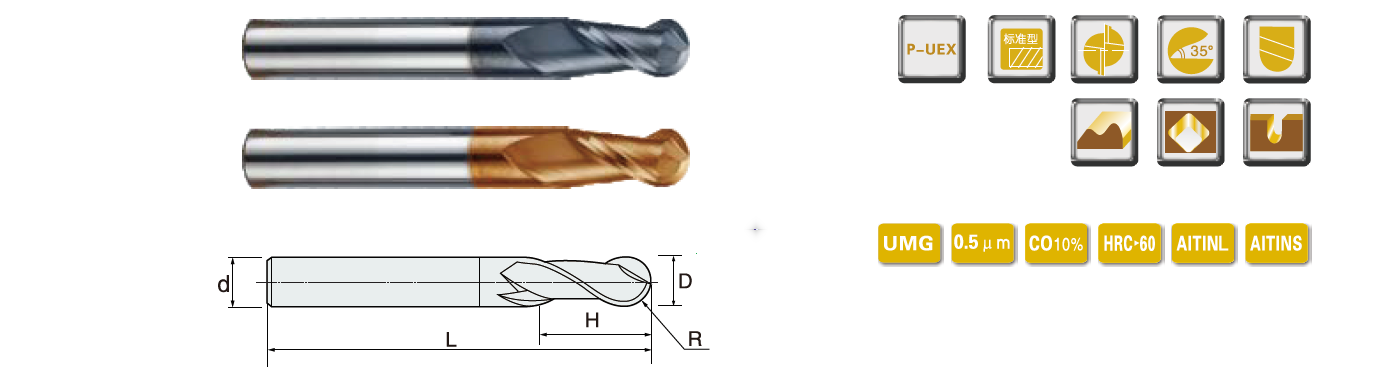

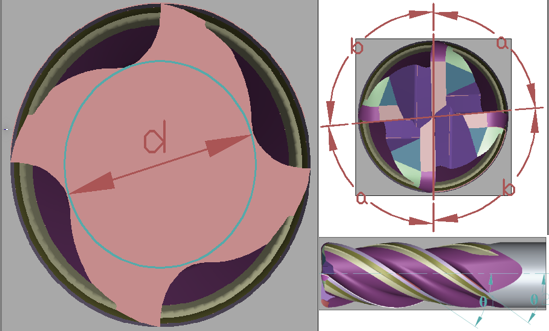

. Chamfering passivation protection, life improved by at least 30%

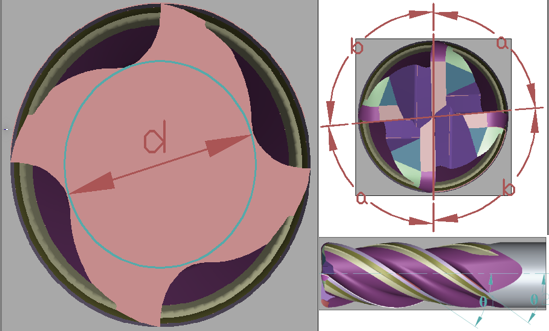

. a≠b Unequal pitch , θ1≠θ2 Variable helix ,improve anti-vibration

. The ultra-micro passivation process of about 12um greatly increases around 4 timex of its life time

. Sharp and strong design ,for 35 °~60° Hardened steel

. Straight type Design for Minimizing edge chipping.

. High precision surface processing.

. A variety of flute lengths are available

. Recommended high speed 12000 ~ 20000rpm, oil mist cooling.

Specification

| specification | R | Flute L | Shank | Overall L |

| standard | R0.5X2XD3X50L | R0.5 | 2 | 3 | 50 |

| R1.0X4XD3X50L | R1 | 4 | 3 | 50 |

| R0.50X2XD4X50 | R0.5 | 2 | 4 | 50 |

| R0.50X2XD6X50 | R0.5 | 2 | 6 | 50 |

| R0.75X3XD4X50 | R0.75 | 3 | 4 | 50 |

| R0.75X3XD6X50 | R0.75 | 3 | 6 | 50 |

| R1.00X4XD4X50 | R1 | 4 | 4 | 50 |

| R1.00X4XD6X50 | R1 | 4 | 6 | 50 |

| R1.25X5XD4X50 | R1.25 | 5 | 4 | 50 |

| R1.25X5XD6X50 | R1.25 | 5 | 6 | 50 |

| R1.50X6X3X50 | R1.5 | 6 | 3 | 50 |

| R1.50X6XD4X50 | R1.5 | 6 | 4 | 50 |

| R1.50X6XD6X50 | R1.5 | 6 | 6 | 50 |

| R1.75X7XD4X50 | R1.75 | 7 | 4 | 50 |

| R1.75X7XD6X50 | R1.75 | 7 | 6 | 50 |

| R2.00X8XD4X50 | R2.0 | 8 | 4 | 50 |

| R2.00X8XD6X50 | R2.0 | 8 | 6 | 50 |

| R2.25X9XD6X50 | R2.25 | 9 | 6 | 50 |

| R2.50X10X5X50 | R2.5 | 10 | 5 | 50 |

| R2.50X10X6X50 | R2.5 | 10 | 6 | 50 |

| R2.50X10X6X60 | R2.5 | 10 | 6 | 60 |

| R2.75X11XD6X50 | R2.75 | 11 | 6 | 50 |

| R2.50X10XD6X50 | R2.5 | 10 | 6 | 50 |

| R3.00X12XD6X50 | R3.0 | 12 | 6 | 50 |

| R3.25X13XD8X60 | R3.25 | 13 | 8 | 60 |

| R3.50X14XD8X60 | R3.5 | 14 | 8 | 60 |

| R3.50X14XD7X60 | R3.5 | 14 | 7 | 60 |

| R3.75X15XD8X60 | R3.75 | 15 | 8 | 60 |

| R4.00X16XD8X60 | R4.0 | 16 | 8 | 60 |

| R4.50X18XD10X75 | R4.5 | 18 | 10 | 75 |

| R5.00X20XD10X75 | R5.0 | 20 | 10 | 75 |

| R6.00X24XD12X75 | R6.0 | 24 | 12 | 75 |

| R7.00X40XD14X100 | R7.0 | 40 | 14 | 100 |

| R8.00X40XD16X100 | R8.0 | 40 | 16 | 100 |

| R8.00X30XD16X100 | R8.0 | 30 | 16 | 100 |

| R9.00X40XD18X100 | R9.0 | 40 | 18 | 100 |

| R10.0X40XD20X100 | R10.0 | 40 | 20 | 100 |

| R12.5X40XD25X100 | R12.5.0 | 40 | 25 | 100 |

| Long shank | R0.50X2XD4X75 | R0.5 | 2 | 4 | 75 |

| R0.5X2XD4X100 | R0.5 | 2 | 4 | 100 |

| R0.50X2XD6X100 | R0.5 | 2 | 6 | 100 |

| R0.75X3XD4X75 | R0.75 | 3 | 4 | 75 |

| R0.75X3XD4X100 | R0.75 | 3 | 4 | 100 |

| R0.75X3XD6X100 | R0.75 | 3 | 6 | 100 |

| R1.00X4XD4X75 | R1 | 4 | 4 | 75 |

| R1.00X4XD6X75 | R1 | 4 | 6 | 75 |

| R1.00X4XD4X100 | R1 | 4 | 4 | 100 |

| R1.00X4XD6X100 | R1 | 4 | 6 | 100 |

| R1.25X5XD4X75 | R1.25 | 5 | 4 | 75 |

| R1.25X5XD6X100 | R1.25 | 5 | 6 | 100 |

| R1.5X6X3X75 | R1.5 | 6 | 3 | 75 |

| R1.50X6XD4X75 | R1.5 | 6 | 4 | 75 |

| R1.5X6XD6X75 | R1.5 | 6 | 6 | 75 |

| R1.5X6XD3X100 | R1.5 | 6 | 3 | 100 |

| R1.50X6XD4X100 | R1.5 | 6 | 4 | 100 |

| R1.50X6XD6X100 | R1.5 | 6 | 6 | 100 |

| R1.75X7XD4X75 | R1.75 | 7 | 4 | 75 |

| R1.75X7XD6X100 | R1.75 | 7 | 6 | 100 |

| R2.00X8XD4X75 | R2.0 | 8 | 4 | 75 |

| R2.00X8XD6X75 | R2.0 | 8 | 6 | 75 |

| R2.0X8X4X100 | R2.0 | 8 | 4 | 100 |

| R2.00X8XD6X100 | R2.0 | 8 | 6 | 100 |

| R2.25X7XD6X75 | R2.25 | 7 | 6 | 75 |

| R2.25X9XD6X100 | R2.25 | 9 | 6 | 100 |

| R2.5X10XD5X75 | R2.5 | 10 | 5 | 75 |

| R2.50X10XD6X75 | R2.5 | 10 | 6 | 75 |

| R2.50X10XD5X100 | R2.5 | 10 | 5 | 100 |

| R2.50X10XD6X100 | R2.5 | 10 | 6 | 100 |

| R2.75X11XD6X75 | R2.75 | 11 | 6 | 75 |

| R2.75X11XD6X100 | R2.75 | 11 | 6 | 100 |

| R3.00X12XD6X75 | R3.0 | 12 | 6 | 75 |

| R3.00X12XD6X100 | R3.0 | 12 | 6 | 100 |

| R3.00X12XD6X150 | R3.0 | 12 | 6 | 150 |

| R3.00X20XD6X100 | R3.0 | 20 | 6 | 100 |

| R3.00X20XD6X120 | R3.0 | 20 | 6 | 120 |

| R3.00X20XD6X150 | R3.0 | 20 | 6 | 150 |

| R3.00X30XD6X150 | R3.0 | 30 | 6 | 150 |

| R4.00X16XD8X75 | R4.0 | 16 | 8 | 75 |

| R4.00X16XD8X100 | R4.0 | 16 | 8 | 100 |

| R4.00X16XD8X150 | R4.0 | 16 | 8 | 150 |

| R4.00X16XD8X200 | R4.0 | 16 | 8 | 200 |

| R4.00X20XD8X120 | R4.0 | 20 | 8 | 120 |

| R4.00X30XD8X150 | R4.0 | 30 | 8 | 150 |

| R5.00X20XD10X100 | R5.0 | 20 | 10 | 100 |

| R5.00X20XD10X150 | R5.0 | 20 | 10 | 150 |

| R5.00X20XD10X200 | R5.0 | 20 | 10 | 200 |

| R5.00X25XD10X120 | R5.0 | 25 | 10 | 120 |

| R5.00X40XD10X150 | R5.0 | 40 | 10 | 150 |

| R6.00X24XD12X100 | R6.0 | 24 | 12 | 100 |

| R6.00X24XD12X150 | R6.0 | 24 | 12 | 150 |

| R6.00X24XD12X200 | R6.0 | 24 | 12 | 200 |

| R6.00X25XD12X100 | R6.0 | 25 | 12 | 100 |

| R6.00X30XD12X120 | R6.0 | 30 | 12 | 120 |

| R6.00X40XD12X150 | R6.0 | 40 | 12 | 150 |

| R7.00X30XD14X150 | R7.0 | 30 | 14 | 150 |

| R7.00X30XD14X200 | R7.0 | 30 | 14 | 200 |

| R7.00X40XD14X150 | R7.0 | 40 | 14 | 150 |

| R8.00X30XD16X150 | R8.0 | 30 | 16 | 150 |

| R8.00X30XD16X200 | R8.0 | 30 | 16 | 200 |

| R8.00X40XD16X150 | R8.0 | 40 | 16 | 150 |

| R9.00X40XD18X150 | R9.0 | 40 | 18 | 150 |

| R10.00X30XD20X150 | R10.0 | 30 | 20 | 150 |

| R10.00X30XD20X200 | R10.0 | 30 | 20 | 200 |

| R10.00X40XD20X150 | R10.0 | 40 | 20 | 150 |

Detailed Images

. a≠b Unequal pitch , θ1≠θ2 Variable helix ,improve anti-vibration

Detailed Images

Product Name | Carbide end mill | unequal pitch | 88º/92º |

Brand | DOHRE.. | Coating | InoxaCon |

Hardness | HRC60 | Place of Product | Guangdong Province,China |

Raw material | GU25 | Aplication | Precision mirror mold, HRC50°-60° material, fine milling processing |

Agent | Welcome to be agent | Stock | Huge stock |

application type

Material :2343ES die steel, hardened steel,Automobile lamp mold

Coating

| Working piece\ Coating | ATN | ALLX | ACO | DLC-S | Ta-C |

| Die steel |

|

|

|

|

|

| 38-55HRC |

| ▲ |

|

|

|

| up to 55HRC |

| ▲ | ▲▲ |

|

|

| Stainless steel (304/316) | ▲ |

|

|

|

|

| Aluminum alloy |

|

|

| ▲ | ▲▲ |

| Copper alloy |

|

|

| ▲ | ▲▲ |

| titanium alloy |

|

| ▲ |

|

|

| Coating\ Performance | ATN | ALLX | ACO | DLC-S | Ta-C |

| Color | Gray-black | Bronze | Dark grey | Black | colorful |

| Vickers hardness(HV) | 3,500 | 4,300 | 4,400 | 2,500 | 5,000 |

| Coating thickness(卩m) | 0.5-4.0 | 0.5-3.0 | 0.5-4.0 | 0.5-5.0 | 0.1-0.3 |

| friction coefficient | 0.25 | 0.3 | 0.3 | 0.10-0.15 | 0.05-0.10 |

Advantages

Advantages:

> Cutting Edge passivated to 10um, extend tool life.

> Thick negative rake design, suitable for processing hard steel up to 60HRC.

> Double rear corners to avoid empty space to increase chip removal.

> Unequal spiral angle design prevents from vibration.

> Well coating with Cemecon(Germany)) coated to increase tool toughness and pro-long tool life.